Guitar making Products - All available on Ebay

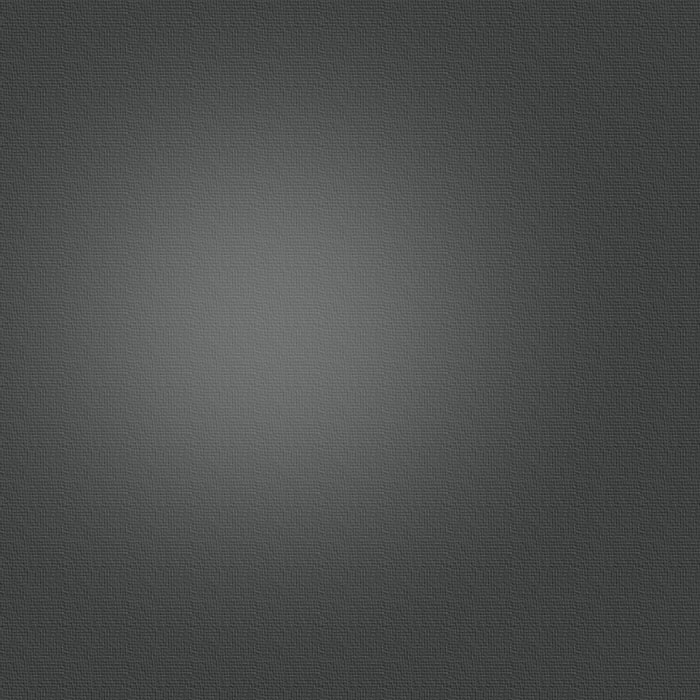

FRET SLOTTING JIG AND SCALE LENGTH TEMPLATES

Like many other before me, when I decided that I wanted to make my own fretboards the first thing I ordered was a StewMac jig, saw and scale template with a single scale length marked down either side.

This was fine for my first two guitars which were built on the Martin 25.34” scale. However, when I wanted to build a Maccaferri copy, I had to CNC machine my own scale template as the Maccaferri scales are not available from StewMac or any of the other suppliers of similar jigs.

This got me thinking as to why the jig itself needed to be so complex and cost several hundred pounds and why the templates, also expensive at around £40 each, be limited to only two scale lengths and available in such a narrow range of options.

After a weekend of ‘playing’ in the workshop, I had come up with a working prototype which I shipped off to a member of the guitarmaking.co.uk forum for assessment.

Initial feed back was very positive and a couple of suggested improvements, such as using solid laminate for the guide bushes, were incorporated into the final production model which is now available for sale on eBay for a fraction of the price of the StewMac jig.

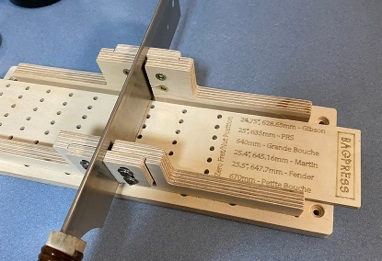

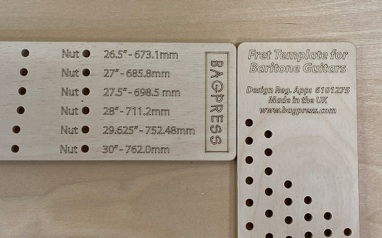

The revolutionary aspects of my jig and templates are, firstly, that they are made out of top quality birch plywood and high pressure laminate keeping the costs down and, secondly, that by incorporating a moveable index pin in the base, it has been possible to include six scale lengths on each template.

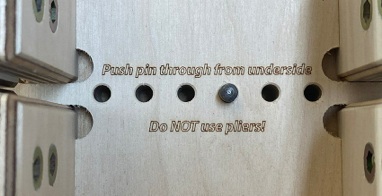

Instructions for use and adjustment are laser engraved onto the jig itself so there is no paperwork to lose.

The accuracy of the template drilling has been independently assessed as being slightly better than that of the metal StewMac products and allowance is even made for scale lengths that usually incorporate a Zero fret, as is the case with those for the Maccaferri guitars.

Whilst the use of plywood may alarm some makers I must point out that this an extremely stable and hardwearing material and each template hole is only used once for each fret board cut. I doubt that any noticeable wear would be detectable even after cutting more than fifty identical fretboards.

As well as the standard mixed electric/acoustic template there are four others available covering electric, acoustic, baritone and bass scale lengths. I believe this is the most complete set of templates available for any fret slotting jig currently being made and covers more than 20 different scale lengths.

I also supply top quality fret slotting saws made in Sheffield

and these are supplied with self adhesive PTFE glass cloth which helps reduce friction.

The prices are:

Fret Slotting Jig £80 inc VAT

Scale Length Templates £30 inc VAT

Fret Slotting Saw £37.50 inc VAT

NECK POCKET ROUTING JIG

One of the most common questions that I would see posted in the forums related to fixing sloppy neck joints and so I came up with a solution to this problem.

Instead of machining a pocket and then trying to make a neck to fit it, my jig works to other way around. The neck is made to finished dimension and then this is used to to set the neck pocket jig to the exact size and geometry of the neck.

I suggest that the adjustable master template be used to cut a ‘working’ template which is then used when machining the neck pocket. This allows for a great depth of cut in the guitar body and also reduces the likelihood of the main jig being damaged. Working template blanks can be order at very low cost.

The adjustable side plates are pushed up against the sides of the neck and the screws tightened to hold them in place.

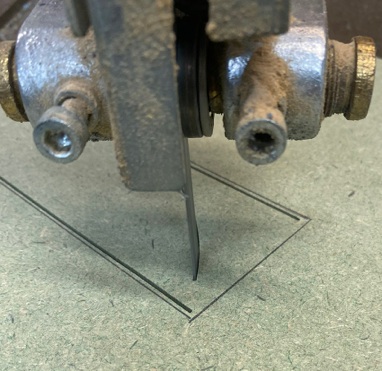

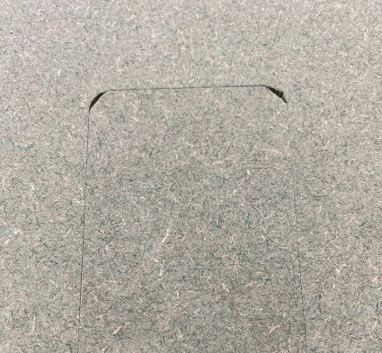

The working template is then marked and most of the waste cut out on the bandsaw.

It is then screwed to the master template and a bearing guided router cutter used to trim the recess to the exact shape/size of the neck.

The working template can be compared to the neck to check for the tighness of fit. Very small adjustments can then be made to the neck with a sanding block if required but this is not usually necessary unless your cutter/bearing is worn.

Neck Pocket Jig £48 inc VAT

Working Template Blanks £2 inc VAT each

STOCK FLATTENING JIG

Whilst the majority of amateur guitar makers will have a router not all have access to a planer/thicknesser capable of being used to machine rough sawn timber for guitar bodies. There are many videos of jigs similar to mine available on YouTube and this isn’t a particularly difficult jig to make yourself. However, many makers just prefer to get on with making their guitars rather than spending hours on producing machine accessories such as this.

The jig consists of a base and a sliding gantry. The two side guides on the gantry can be adjusted to accommodate most makes of router.

The slab of rough sawn timber is screwed to the base of the jig from underneath and the corners can be packed out to increase stability if required.

The router is fitted with a guide bush very slightly larger than the diameter of the cutter being used. I suggest a cutter with a diameter of around 20-25mm as this will allow a reasonable depth of cut whilst keeping the number of passes required to a minimum.

After each pass the gantry is moved along slightly and another cut taken producing a uniform flat surface.

Once the entire first side has been machined the slab is turned over and the process repeated for the second side.

The surface will still need to finally cleaned up with a hand plane or sander but it is now perfectly flat and of uniform thickness.

The maximum size of material that can be machined is approx 52mm thick x 600mm long x 410mm wide.

Stock Flattening Jig £115 inc VAT